What is 3D printing?

3D printing is an additive manufacturing process, meaning that the object is created by adding layers rather than shaped by removing material. The basis of it is taking a 3D digital model and slicing it into very thin layers. These layers are printed from the bottom up, one on top of the other, and together form a solid object.

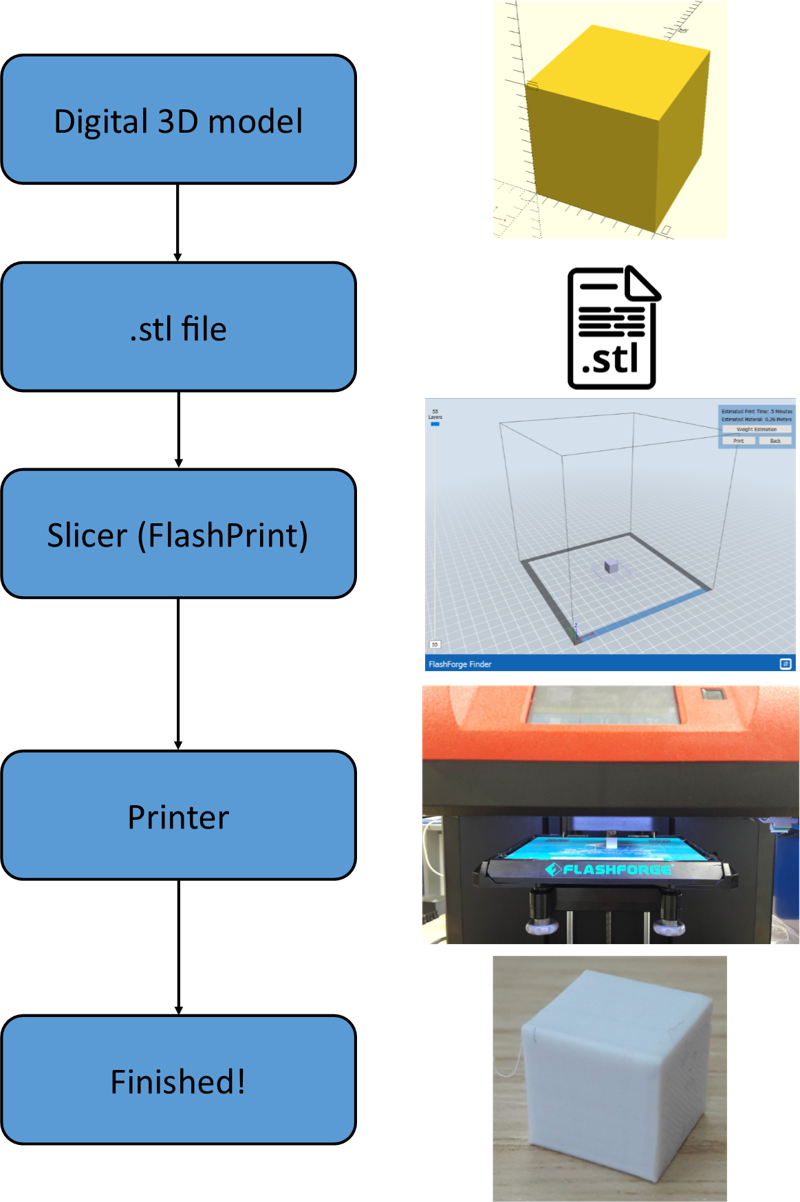

Method

The model is designed on a computer first; this process is referred to as CAD (computer aided design). This can be done through a variety of software but we shall be focusing on OpenSCAD, Tinkercad and Blender. There is also a guide discussing the relative benefits and drawbacks of different modelling programs.

It is also possible to retrieve already existing models that other people have designed through online sites. The most notable of these sites being Thingiverse. For more information, see the guide on how to use these websites.

Once the model has been designed, it is exported as an .stl file. This file type is standard in the industry and can be read by the majority of printer software - in our case the software is called FlashPrint. The printer software takes the digital model and slices it into very thin, horizontal layers. It saves these layers as a .gx file, which is a set of instructions that the printer can read and then follow to create the object.

The .gx file is transferred to the printer (this method may vary from printer to printer) but is typically done through a wired connection, USB (FlashForge Finder) or SD card (FlashForge Dreamer).

Once the print is complete, the printer will display a message informing you that it is safe to remove the model. Any supports, brims or rafts added to the print must be removed manually.

Materials

You can 3D print with a wide range of materials - broadly, the only requirement is that they can be fed into the nozzle, melted, and cooled down quickly.

PLA is a cheap and versatile 3D printing material. It is a thermoplastic aliphatic polyester, meaning it is pliable at higher temperatures and not actually an acid. PLA is made from renewable biomass.

Other materials are available such as nylon, resin, and even metals such as stainless steel in high quality 3D printers. There are many different reasons for choice of material: withstanding high temperatures, durability or weight of models. These different properties are all specified and weighed up here.

We mainly use PLA because it is cheap, recyclable and non-toxic. A kilogram of PLA costs around £30.

How does it work?

3D printing works in very much the same way as 2D printing, except with several more layers and a different material to ink.

The extruder moves in the plane and the plate moves in the direction. Each new layer is created by lowering the plate by the thickness of the layer.

Different models take a range of times to print due to differences in the design. There are multiple reasons why some models may take a longer time to complete, for example if the the design is very large, there are many small features in the design, or multiple parts that the printer must move between.

It takes approximately 16 minutes to print a 2cm sided cube on the FlashForge Finder, but square and cube laws don’t apply directly when scaling shapes because of infill. A 4cm sided cube would be expected to take roughly times longer to create, but it actually only takes 5 times longer due to the hollow nature of the shapes. More complex designs will take slightly longer as the printer covers the intricacies, so larger designs may need to be left overnight to allow them to be completed.

For models that need to be ’filled in’ such as a solid cube, the printer uses honeycombing to create a solid support for anything above that point in the model, but minimise time and plastic used in making the model. This hexagonal pattern acts as a sturdy support for the rest of the model, and demonstrates why models are much lighter than a non-hollow plastic alternative. Other infill methods are described here.

Should the model’s design feature an overhang, it might not be able to print accurately. Typically printers can handle an overhang of up to 45 degrees. This is because there are less/no layers to print directly onto when exceeding 45 degrees. To amend this, the overhang must be supported either by altering the model or generating supports automatically in Flashprint.

Benefits of 3D printing

Relatively low start up cost (don’t need to pay for expensive, unique molds as used in injection molding)

Easily customisable at no extra cost

Only have to pay for the material used, so relatively cheap for one offs

Relatively quicker and thus speeds up the design cycle as a whole

Can be done by anyone and easy to do a trial before purchasing a 3D printer - through an online CAD software (such as TinkerCAD) and sending the .stl file to a 3D printing company

Drawbacks of 3D printing

Complex shapes are hard to make if they aren’t available online.

Time consuming if models are being completed to a high or hyper quality.

Limited sizes and shapes of models can be made for the Finder (cm), slightly larger for Dreamer (cm) but not unlimited.

Supports etc can be hard to remove from some models.

Not always possible to watch a full print take place, if an error occurs (running out of filament, plastic coming off the plate etc) it could be left running if not being watched.

Smoother shapes like spheres depend on the printer quality, for very high resolution it would require an expensive

Uses of 3D printing

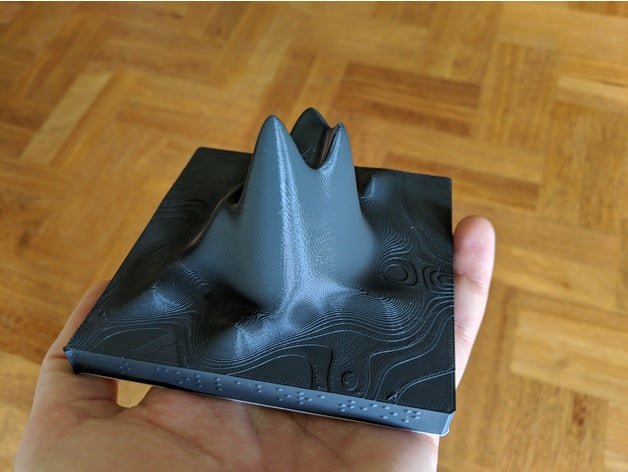

3D printing means that it is possible to print off tactile aids for visually impaired people. Braille can be printed very easily. There are websites (such as Touch See) dedicated to converting various languages into braille (and then downloading directly as an .stl file).

Data can be more widely visualised with 3D printing, through height maps.

3D printing can create height maps from 2D images, so heat maps and other data can be more easily accessed by the visually impaired. Someone even printed the black hole that was discovered into a tactile image.

Medical professionals use 3D printing in operations such as the separation of conjoined twins.

Many people have used 3D printing as part of mathematical demonstrations. Henry Segerman is a particularly prolific creator of mathematical objects, and has written a book about his work.